Calcination of magnesium hydroxide and raw material ratio: key factors for improving the compressive strength of magnesium oxychloride cement

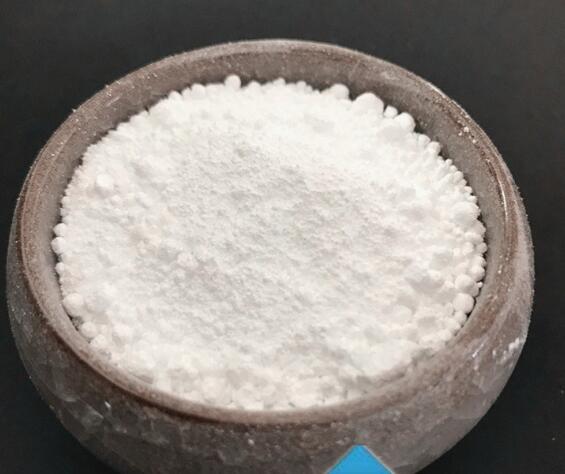

Magnesium oxychloride cement (MOC), as a high-performance building material, has attracted more and more attention in the field of modern construction due to its unique physical and chemical properties. Magnesium hydroxide (Mg(OH)_2) is a key raw material for preparing magnesium oxychloride cement. Its calcination process and raw material ratio have a decisive impact on the final performance of cement.

Fine control of calcination process

Calcination temperature and time: Precise control of calcination conditions, especially temperature and duration, is the key to obtaining highly active magnesium oxide (MgO). Highly active MgO is crucial to the hydration reaction of magnesium oxychloride cement and the formation of gel network structure. Cooling rate: The cooling rate of MgO after calcination is equally important. It affects the size and distribution of grains and indirectly determines the properties of cement. Optimization of raw material ratio

The ratio of MgO: MgCl_2: H_2O: This ratio is the key to ensuring that magnesium oxychloride cement forms a stable gel phase (5-1-8 phase), which plays a decisive role in the compressive strength of cement. Sand rate and additives: The content and type of sand, as well as the use of additives such as retarder and early strength agent, will also affect the density and pore structure of cement, thereby affecting its compressive strength. Empirical analysis of research examples

Zheng Weixin's research and orthogonal test results show that by optimizing the calcination process of magnesium hydroxide and the raw material ratio of magnesium oxychloride cement, the compressive strength of cement can be significantly improved. Finely controlling the calcination process of magnesium hydroxide and optimizing the raw material ratio are of great significance for improving the compressive strength of magnesium oxychloride cement. This can not only enhance the engineering application performance of materials, but also promote technological progress and innovation in the building materials industry.

With the in-depth research on the preparation process of magnesium oxychloride cement, it is expected that more high-performance building materials will be developed to meet the high standards of modern construction for safety, environmental protection and durability.