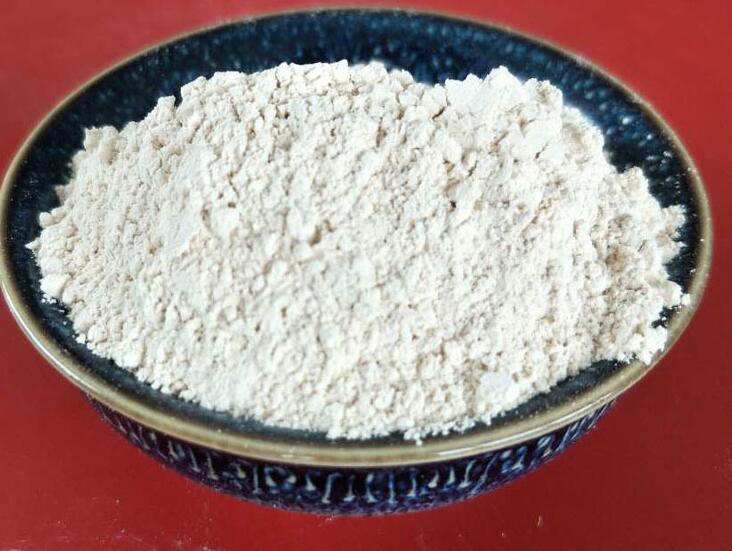

Research on surface modification technology of nano-magnesium hydroxide: optimizing dispersibility and enhancing application performance

Due to its unique physical and chemical properties, nanomagnesium hydroxide (nano-Mg(OH)_2) has shown wide application potential in the fields of flame retardant materials, medicine, catalysts, adsorbents and composite materials. However, the agglomeration problem of nanoparticles and poor interfacial compatibility with matrix materials limit the full use of their properties. Therefore, surface modification has become one of the key technologies to improve the application performance of nanomagnesium hydroxide. The following are several important aspects of research on surface modification of nano-magnesium hydroxide:

Modification purpose

Improve dispersibility: Reduce the van der Waals force between particles through modification, prevent agglomeration, and make it more evenly dispersed in various media (such as polymer matrices). Enhance interface compatibility: Improve the bonding force between nanoparticles and substrates, and improve the comprehensive performance of composite materials. Functional enhancement: Give nano magnesium hydroxide new functional properties, such as improved flame retardancy, improved thermal stability, enhanced biocompatibility, etc. Modification method

Chemical modification: Coupling agent modification: Use silane coupling agents, titanate coupling agents, etc. to form an organic coating layer on the surface of nanoparticles through chemical reactions to improve its hydrophobicity and compatibility with organic matrices. Graft modification: Graft polymer chains on the surface of nanoparticles through polymerization reactions to further improve their dispersibility and interfacial bonding strength. Physical modification: Coating treatment: Use inorganic or organic molecules to physically wrap nanoparticles, such as through deposition, adsorption, etc. Mechanochemical method: Use physical methods such as ball milling and ultrasonic treatment to destroy the surface of particles and introduce active points to facilitate subsequent chemical modification. Sol-gel method: The surface of nanoparticles is modified in the sol stage, and the modified layer is then fixed through a gelation process. Evaluation of modification effect

Characterization technology: Evaluate nano-hydrogen before and after modification through X-ray diffraction (XRD), transmission electron microscope (TEM), scanning electron microscope (SEM), Fourier transform infrared spectroscopy (FTIR), thermogravimetric analysis (TGA), etc. Structure, morphology, composition and thermal stability of magnesium oxide. Dispersion and compatibility test: Evaluate the impact of modification on dispersion and compatibility with matrix materials through sedimentation experiments, contact angle measurements, dynamic light scattering (DLS) and other methods. Applications

Composite materials: As a flame retardant filler in polymer materials such as polypropylene (PP), polyethylene (PE), and natural rubber (NR), modified nanomagnesium hydroxide can significantly improve the flame retardant properties and performance of composite materials. mechanical properties. Drug carrier: Surface-modified nanomagnesium hydroxide can be used as a sustained-release carrier for drugs to improve the bioavailability and targeting of drugs. Environmental protection: As an adsorbent, it is used in wastewater treatment and air purification. After modification, it can enhance its adsorption capacity for specific pollutants. In summary, the research on the surface modification of nano-magnesium hydroxide is a multidisciplinary field. By finely regulating the modification strategy, its application range can be greatly broadened and its application efficiency can be improved.