Environmental protection technology and market prospects of magnesium hydroxide flame retardant converted from phosphate tailings

Globally, the rapid development of the phosphorus chemical industry has brought a large amount of phosphate tailings waste. How to convert these wastes into products with economic value and environmental significance has become a research hotspot in the field of materials science. Magnesium hydroxide (Mg(OH)_2) is an efficient inorganic flame retardant, and the research progress in its preparation technology provides new ideas for the reuse of phosphate tailings.

Key steps in raw material pretreatment

Pretreatment of phosphate tailings is the first step in the preparation of magnesium hydroxide. Physical and chemical methods are used to remove impurities, improve the extraction efficiency of magnesium, and lay the foundation for subsequent chemical reactions. Diversified preparation processes

The researchers explored a variety of chemical reaction pathways, including direct precipitation, carbonization, and in-situ modification, to achieve efficient conversion of phosphate tailings to magnesium hydroxide.

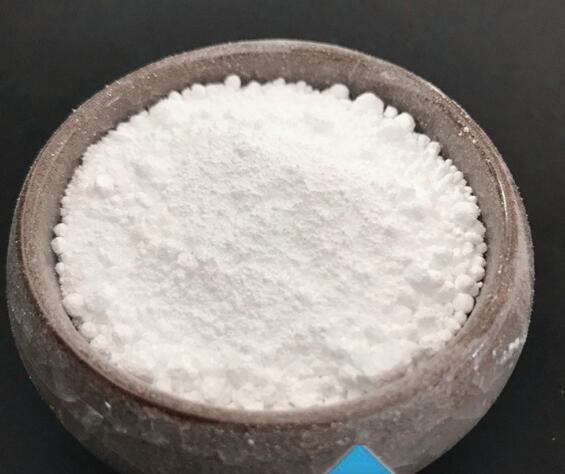

The application of surface modification technology, such as the use of silane coupling agents and organic acids, significantly improves the compatibility of magnesium hydroxide with the polymer matrix and enhances its flame retardant efficiency and mechanical properties in composite materials. Comprehensive performance evaluation

The prepared magnesium hydroxide flame retardant needs to be tested for particle size distribution, purity, thermal stability and flame retardancy to ensure that it meets the application requirements in the fields of plastics, rubber, cable materials, etc. Dual considerations of environmental and economic benefits

During the research process, a comprehensive assessment of environmental impact and cost-effectiveness was conducted to ensure the environmental friendliness and economic feasibility of the preparation process. Conclusion and Market Prospects The technology of preparing magnesium hydroxide flame retardant from phosphate tailings not only solves the environmental problems of phosphate tailings, but also provides a new source of environmentally friendly raw materials for the field of flame retardant materials. With the maturity of technology and the expansion of market demand, research and application in this field will continue to deepen, showing broad market prospects and important social, economic and environmental values.