Brucite: Industrial application and advantages of environmentally friendly magnesium hydroxide flame retardant

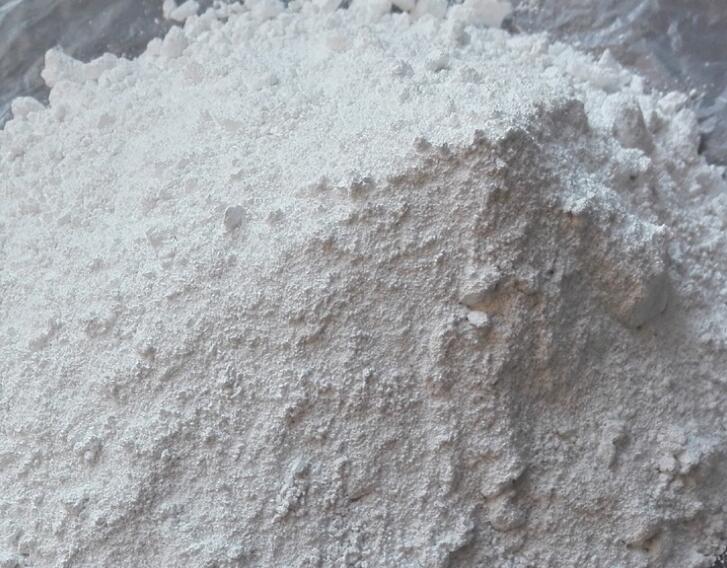

Brucite, whose chemical name is magnesium hydroxide (Mg(OH)_2), is a natural mineral that plays an important role in industry, especially as a flame retardant, due to its unique chemical and physical properties. The following is an overview of the application of brucite in the production of magnesium hydroxide flame retardants:

Characteristics and advantages of brucite

Non-halogen flame retardant: As a halogen-free flame retardant, brucite produces less harmful gases during combustion than traditional halogen flame retardants, is more environmentally friendly and safe, and conforms to the environmental protection trend of modern flame retardant materials. High decomposition temperature: The initial decomposition temperature of brucite is relatively high, generally around 320°C, which is higher than similar flame retardants such as aluminum hydroxide (about 220°C), which makes it more suitable for use in polymer materials with higher processing temperatures. Versatility: In addition to being flame retardant, brucite can also be used as a filler to provide additional physical enhancement effects, such as increasing the hardness and dimensional stability of the material. Smoke suppression effect: The water vapor released when brucite decomposes under heat can effectively suppress the generation of smoke during the combustion process, reduce visibility problems during fires, and increase escape opportunities. Production process

Selection and purification: Select high-quality brucite from natural ores, remove impurities through physical beneficiation, and improve the purity of raw materials. Ultrafine grinding: Ultrafinely crush the selected brucite to reduce the particle size and improve its dispersibility and flame retardant efficiency in polymers. Surface modification: Surface modification of finely ground brucite is performed by chemical methods, such as using silane coupling agents, to improve its compatibility with polymers, reduce agglomeration, and further improve the flame retardant effect and the overall performance of the material. Application areas

Plastic and rubber industry: widely used in plastic and rubber products such as polyolefins, polyurethanes, and cable sheaths to improve their flame retardant properties. Electronic products: used as flame retardant fillers in circuit boards and housing materials to protect electronic products from fire hazards. Building materials: used to manufacture fire retardant coatings, fire retardant panels, etc. to improve the fire safety level of buildings. Textiles: after special treatment, it can also be used for flame retardant finishing of textiles to improve the flame retardant properties of textiles. With its abundant natural resources, excellent flame retardant properties and environmental friendliness, brucite occupies an important position in the production of magnesium hydroxide flame retardants. With the advancement of technology and the improvement of environmental protection requirements, its application scope and market demand will continue to expand.