Innovative preparation and performance of nano-magnesium hydroxide/hexagonal boron nitride nanocomposites

The research and development of nanocomposites occupy an important position in the field of materials science. In particular, nano-magnesium hydroxide/hexagonal boron nitride (Mg(OH)_2/h-BN) nanocomposites have become a hot topic of research due to their excellent performance. This article will outline the preparation methods of the composites and their potential applications.

Key preparation steps

Nano-stripping of hexagonal boron nitride: First, hexagonal boron nitride is stripped into nano-flakes or particles by physical or chemical methods to increase its specific surface area and create conditions for composites.

Precise control of mixing reaction: Nano-hexagonal boron nitride powder is mixed with magnesium chloride solution to form a uniform mixing system, and then sodium hydroxide solution is added to trigger the chemical reaction.

Formation of nanocomposites: The addition of sodium hydroxide triggers the formation of nano-magnesium hydroxide, which is composited with hexagonal boron nitride in solution, and may form a compact nanostructure through in-situ growth.

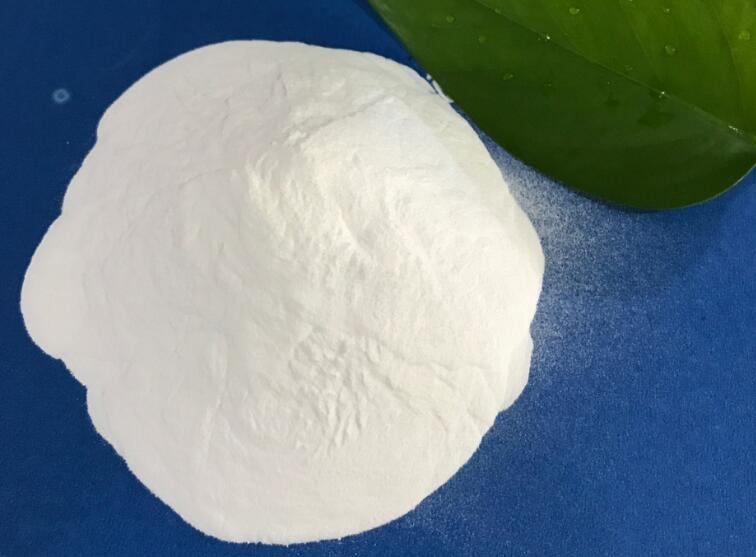

Separation and drying of products: Solid powder is separated by centrifugation or filtration, and the residual medium is removed by washing, and dry nanocomposite powder is obtained by drying process.

Adjustability of composite materials: By adjusting the ratio and dosage of reactants, the loading amount of nano magnesium hydroxide in the composite material can be precisely controlled to achieve composite materials with different properties.

Advantages of nanocomposites

The flame retardant properties of magnesium hydroxide are combined with the high thermal stability and thermal conductivity of hexagonal boron nitride, which significantly improves the flame retardant temperature and structural stability of the material.

At high temperatures, the high temperature resistance of hexagonal boron nitride helps maintain the integrity of the material and effectively delays or prevents the combustion process.

Composite materials may have improved mechanical properties and thermal management capabilities, broadening their application prospects in electronic devices, aerospace, and high-performance flame retardant materials.

The preparation method of nano magnesium hydroxide/hexagonal boron nitride nanocomposites has brought innovative solutions to the field of materials science. By precisely controlling the preparation conditions, composite materials with specific properties can be obtained to meet the needs of modern industry for high-performance materials.

With the continuous deepening of research on nanocomposites, it is expected that more materials with innovative properties will be developed to provide strong support for applications in various industries.