Study on factors affecting the crystal modification effect of brucite powder

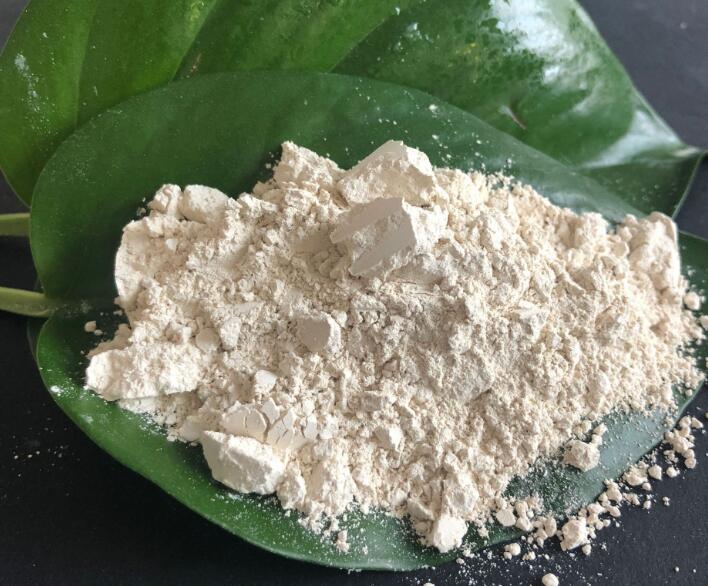

Brucite powder, as a multifunctional material, has application potential in many fields. However, its surface properties directly affect application performance. This study explores various factors that influence the modification effect of brucite powder crystals in order to improve their performance in specific applications.

Key influencing factors

Modifier selection

Carboxylic acid and phosphoric acid modifiers are preferred due to their excellent surface energy reduction effects.

Modifier dosage

The appropriate amount of modifier is crucial to achieve the best modification effect.

Modification temperature

Appropriate modification temperature helps the modifier form stable chemical bonds with the surface of brucite powder.

Modification time

Sufficient modification time ensures uniform distribution of the modifier on the surface of the brucite powder.

Use of additives

The addition of additives can significantly improve the modification effect, especially during the ball milling process.

Ball mill parameters

Ball milling parameters, such as ball-to-material ratio and rotational speed, have an important impact on the particle size and surface state of brucite powder.

other factors

Including the use of surfactants, coupling agents, and composite modification with other flame retardants.

Evaluation of modification effect

The modified brucite powder shows significant improvements in flame retardant properties, surface activity and compatibility.

Application prospects

The application of modified brucite powder in polymer composite materials, especially in the field of flame retardants, shows broad application prospects.

future development

Future research will explore more types of modifiers, optimize the modification process, and develop innovative modification methods.

Comprehensive consideration of modifier selection, dosage, temperature, time and other factors can effectively improve the modification effect of brucite powder. This not only enhances its performance in industrial applications, but also meets market demand for environmentally friendly and high-performance materials.