Study on the technology of recovering magnesium hydroxide from nickel precipitation wastewater of laterite nickel ore by lime milk method

The nickel precipitation wastewater produced by the hydrometallurgy of laterite nickel ore contains a large amount of magnesium ions. The traditional treatment methods have the problems of low efficiency and waste of resources. This study aims to explore a new technical approach to efficiently recover high-purity magnesium hydroxide from these wastewaters through the lime milk method, while improving the filtration rate and optimizing the entire treatment process.

Research background and objectives

Source: The wastewater produced during the hydrometallurgy of laterite nickel ore is rich in magnesium ions.

Target product: magnesium hydroxide (Mg(OH)₂), a multi-purpose inorganic chemical product.

Experimental conditions

Conversion temperature: 80°C

Conversion time: 80 minutes

Lime milk dosage: 95% of the theoretical amount

Dropping rate: 4 mL/min

Main results

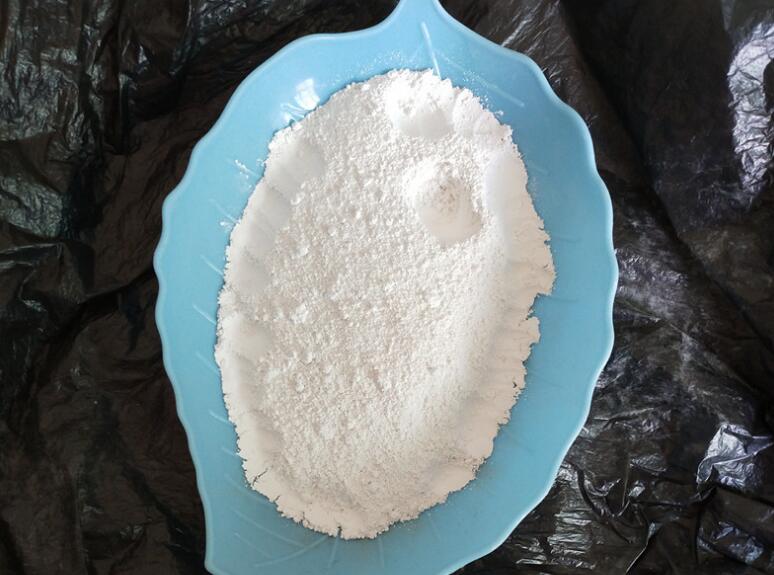

Magnesium hydroxide purity: 99.2%

Filtration rate: 7.37 m³/(m²·h)

Overview of experimental steps

Preparation of lime milk: Accurately prepare a lime milk solution of a specific concentration.

Dropping reaction: The lime milk solution is dropped into the magnesium-containing wastewater at a predetermined rate.

Reaction control: strictly control the reaction conditions, including temperature, time and amount of lime milk.

Filtration and purity detection: after the reaction, filter and collect the magnesium hydroxide precipitate, and perform purity detection.

Performance evaluation: evaluate the filtration speed and other performance indicators.

Technical advantages

High purity: magnesium hydroxide with a purity of up to 99.2% can be prepared.

Good filtration performance: rapid filtration is achieved to improve production efficiency.

Application prospects

Environmental significance: effective recovery of magnesium hydroxide, reduction of wastewater discharge, in line with sustainable development requirements.

Economic benefits: reducing raw material costs and improving corporate economic benefits by recycling magnesium hydroxide.

Further research directions

Optimize the process: conduct in-depth research on better lime milk dosage, reaction temperature and other conditions.

Scale expansion: promote laboratory results to industrial production and achieve large-scale application.

By-product utilization: explore efficient utilization methods of by-products to improve the economy and environmental friendliness of the process.

The technology of recovering magnesium hydroxide from laterite nickel ore nickel precipitation wastewater by lime milk can not only effectively recover high-purity magnesium hydroxide, but also has the potential to increase filtration speed and reduce production costs. This technology helps promote green development in the fields of industrial wastewater treatment and resource recovery.