An efficient strategy to improve the dispersibility of brucite powder flame retardant

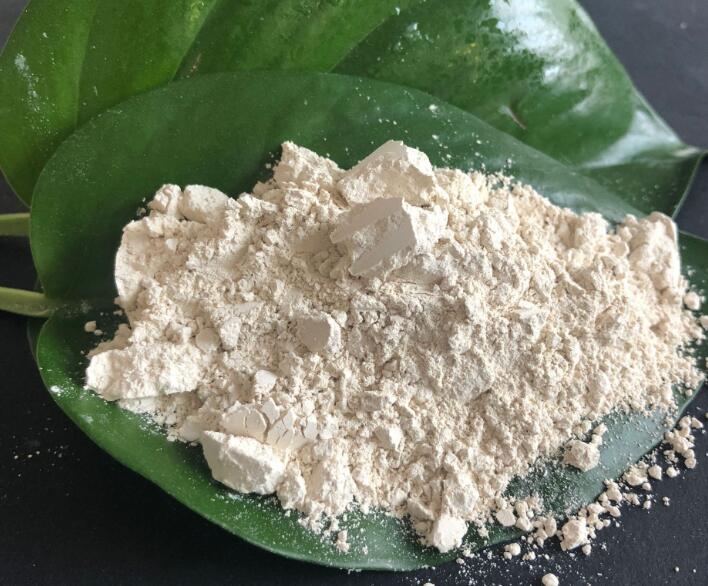

In the field of polymer materials, brucite powder (Mg(OH)₂), as an environmentally friendly and halogen-free flame retardant, is favored for its excellent flame retardant properties and non-toxic properties. However, the dispersion problem of brucite powder in practical applications often becomes a key factor restricting its flame retardant effect and material performance. This article will delve into how to effectively improve the dispersion of brucite powder through scientific dispersant selection and advanced dispersion technology, thereby optimizing its flame retardant performance.

As a new environmentally friendly flame retardant, brucite powder has shown great application potential in polymer materials such as plastics and rubber. However, its dispersion problem in materials has become a bottleneck in improving flame retardant efficiency. This article will share how to overcome this challenge through technological innovation.

Scientific selection of dispersants

Choosing the right dispersant is crucial to improving the dispersion of brucite powder. Here are several effective dispersant options:

Surfactants: such as sodium lauryl sulfate (OT), can significantly improve the dispersion of brucite powder.

Surface modifier: organic modifier such as stearic acid, which can enhance the compatibility between brucite powder and polymer matrix.

Composite dispersant: combines multiple dispersants to achieve better dispersion effects.

Application of efficient dispersion technology

In addition to the choice of dispersant, the use of appropriate dispersion technology is also critical:

Mechanical dispersion: Physically improve the dispersion of brucite powder through high-speed stirring or ball milling.

Ultrasonic dispersion: Utilize the cavitation effect of ultrasonic waves to promote the uniform dispersion of brucite powder in the solution.

Hydrothermal method: Under certain conditions, hydrothermal method can improve the dispersion and crystallinity of brucite powder.

Positive impact of dispersion on flame retardant properties

Good dispersion has a direct positive impact on the flame retardant properties of brucite powder:

Improve flame retardant efficiency: increase the contact area between brucite powder and base material to improve flame retardant efficiency.

Optimize physical properties: Reduce the internal stress of the material and improve the overall performance of the material.

Reduce the amount of addition: By improving dispersion, reduce the amount of brucite powder used and reduce the weight of the material.

, we can see that stearic acid modification can significantly improve the performance of brucite powder under certain conditions. At the same time, ultrasonic dispersion technology shows better dispersion effects than mechanical dispersion.

We realize that through careful selection of dispersants and optimized dispersion technology, the dispersibility of brucite powder can be significantly improved, thereby enhancing its flame retardant properties. Future research will continue to explore the application potential of composite dispersants and optimize dispersion conditions in order to develop higher-performance brucite powder flame retardants to meet the growing market demand for environmentally friendly flame retardant materials.