Study on Preparation of Ultrafine Magnesium Hydroxide by Roasting Serpentine with Ammonium Sulfate

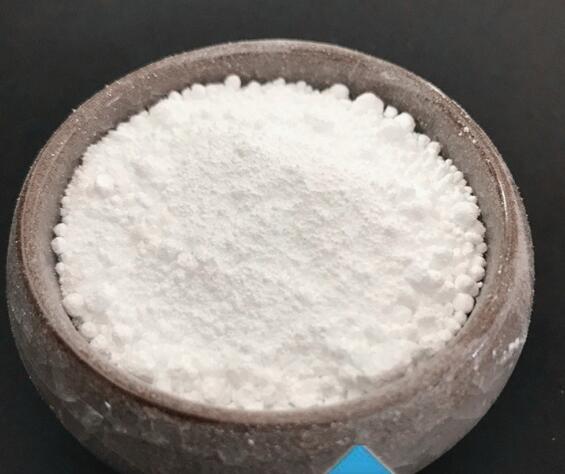

Magnesium hydroxide (Mg(OH)₂) is widely used in plastics, rubber, coatings, ceramics and other fields due to its excellent flame retardant properties, environmental protection and biocompatibility. Traditional preparation methods include precipitation method, hydrothermal method, etc. In recent years, the use of serpentine (a magnesium-containing silicate mineral) as a raw material and the preparation of ultrafine magnesium hydroxide by ammonium sulfate roasting has become a new research hotspot. This method can not only effectively utilize natural resources, but also simplify the process flow and reduce production costs.

Experimental principle

The main component of serpentine is 3MgO·2SiO₂·2H₂O, which is rich in magnesium. By co-roasting with ammonium sulfate ((NH₄)₂SO₄) at high temperature, the magnesium element in serpentine can be released to generate magnesium sulfate (MgSO₄), which is then converted into ultrafine magnesium hydroxide after a series of treatment steps (such as water washing, precipitation, etc.).

Experimental steps

Raw material pretreatment: Select suitable serpentine as raw material, crush and grind it to a certain particle size.

Mixing and roasting: Mix serpentine and ammonium sulfate evenly in a certain proportion, and then roast them under high temperature conditions to make the magnesium in the serpentine react with ammonium sulfate.

Leaching and purification: Leach the roasted product with water or other solvents to dissolve the generated magnesium sulfate and remove other impurities at the same time.

Precipitation and washing: Add an appropriate precipitant (such as ammonia water) to the leaching solution to convert magnesium sulfate into magnesium hydroxide precipitate, and then remove impurities by filtering and washing.

Drying and calcination: Dry the washed magnesium hydroxide precipitate and calcine it if necessary to obtain high-purity ultrafine magnesium hydroxide.

Influencing factors

Roasting temperature: Temperature has a direct impact on the reaction rate and product purity. Too high or too low temperature is not conducive to the complete release of magnesium.

Roasting time: Properly extending the roasting time helps to improve the conversion rate of magnesium.

Raw material ratio: The ratio of serpentine to ammonium sulfate affects the thoroughness of the reaction and the purity of the final product.

Precipitation conditions: Factors such as the selection of precipitants and pH control will also affect the particle size and morphology of magnesium hydroxide.

Performance test

Particle size analysis: Use laser particle size analyzer or transmission electron microscope (TEM) and other equipment to determine the particle size distribution of magnesium hydroxide to ensure that it reaches the ultrafine level.

Purity detection: Use X-ray diffraction (XRD), infrared spectroscopy (FTIR) and other technologies to analyze the purity of the product.

Performance evaluation: Test the key performance indicators of ultrafine magnesium hydroxide such as flame retardancy, hygroscopicity, and thermal stability.

The preparation of ultrafine magnesium hydroxide by serpentine ammonium sulfate roasting method is a feasible technical route. By optimizing the reaction conditions, the purity and performance of the product can be effectively improved. This method not only makes full use of natural resources, but also has the advantages of simple process and low cost, which is of great significance for promoting the industrial production and application of magnesium hydroxide materials.