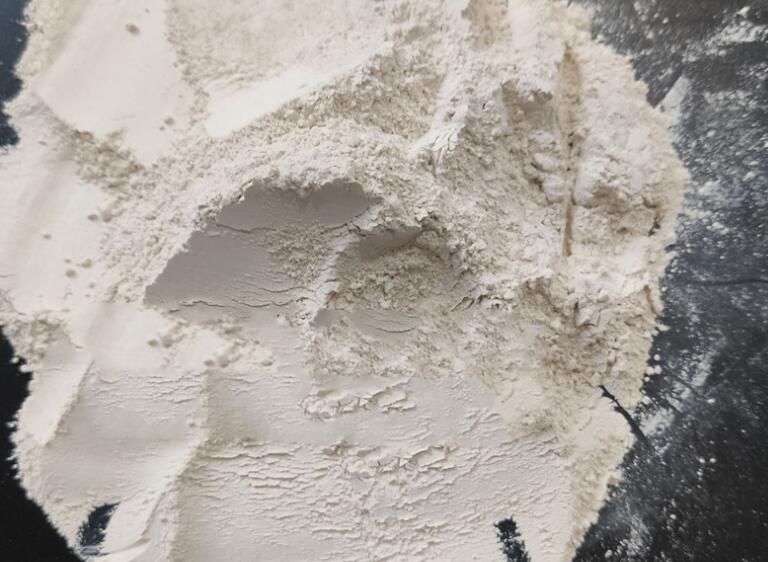

Modified light-burned magnesium oxide fine powder: a small building guard against hydration

In the big family of building materials, light-burned magnesium oxide (MgO) has always been a favorite baby for its fire resistance and thermal shock resistance. But this baby has a small problem - it is easy to absorb water and swell, which is not a good habit. In order to make our little guard stronger, scientists put on a magical anti-hydration coat for it. This article will tell how this coat is made and how it helps light-burned magnesium oxide fine powder maintain its heroic qualities in a humid environment.

In the world of construction, light-burned magnesium oxide (MgO) is a brave warrior. Its fire resistance and thermal shock resistance make it highly favored in the high-temperature industrial field. However, this warrior has a little secret - it doesn't like water. Once it encounters moisture, it will swell and deform, which not only affects its combat effectiveness, but may also shorten its service life.

In order to help this warrior overcome this weakness, scientists decided to design a special coat for it. The main components of this coat are ethylene glycol and polyisobutylene maleic anhydride copolymer (ISOBAM-104), which are mixed, ground and heat-treated to provide a layer of anti-hydration protective layer for the light-burned magnesium oxide fine powder.

During the production process of this coat, scientists discovered a magical ratio - when the addition amount of ISOBAM-104 reaches 7%, after heat treatment at 250°C, the coat has the best anti-hydration effect. After wearing this coat, the hydration mass increase rate of the light-burned magnesium oxide fine powder is significantly reduced to only 2.2%, which is equivalent to giving it a waterproof shield, allowing it to remain strong in a humid environment.

The light-burned magnesium oxide fine powder wearing a new coat not only performs well in building materials, but also shows its prowess in the field of environmental protection materials. It can be used to make water-absorbing materials, help treat sewage and repair soil, and become a small environmental protection guard.

The anti-hydration coat of the light-burned magnesium oxide fine powder not only enhances its application potential in building materials, but also allows it to play a greater role in the field of environmental protection. The manufacturing technology of this coat provides more protection for our building guards, allowing them to maintain their best condition in various environments. Future research will continue to explore more innovative modification methods to make our building guards more powerful and create a safer and more comfortable living environment for humans.