Improving the purity of light-burned magnesium oxide: strategies for removing silica by additives

Light-burned magnesium oxide is widely used in the fields of refractory materials, chemical industry and environmental protection due to its excellent physical and chemical properties. However, impurities in the raw materials, especially silica, will reduce the performance of light-burned magnesium oxide. Therefore, the development of an effective silica removal method is crucial to improve the market competitiveness of light-burned magnesium oxide.

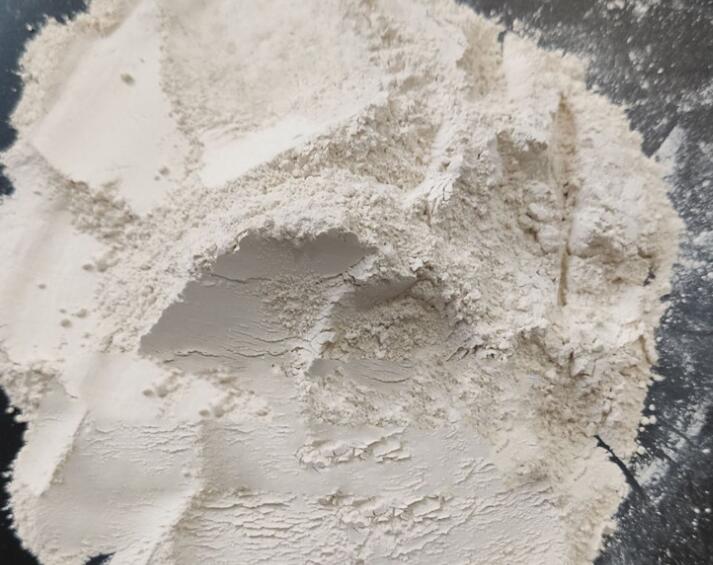

Preparation of light-burned magnesium oxide

Light-burned magnesium oxide is usually prepared by calcining magnesium-containing minerals at a relatively low temperature. Although this process is simple, it is difficult to completely avoid the mixing of silica.

Effect of silica

The presence of silica will reduce the refractory properties and chemical stability of light-burned magnesium oxide, thereby limiting its use in high-end applications.

Selection and mechanism of action of additives

In order to remove silica, alkaline or acidic additives, as well as complexing agents, can be used. These additives react with silica to form soluble substances, which are then removed by water washing.

Alkaline additives such as sodium hydroxide and potassium hydroxide can react with silica to form water-soluble silicates.

Acidic additives such as hydrochloric acid and sulfuric acid can react with silica to form soluble silicates.

Complexing agents such as ethylenediaminetetraacetic acid (EDTA) and citric acid can form stable complexes with silica.

Experimental methods

The experiment removes silica by mixing light-burned magnesium oxide with selected additives and reacting and washing for a certain period of time. The treated samples are dried and tested for performance.

Performance test

The purity and silica content of light-burned magnesium oxide before and after treatment were analyzed by X-ray fluorescence spectroscopy (XRF) and atomic absorption spectroscopy (AAS). At the same time, the physical properties of the samples were evaluated using scanning electron microscopy (SEM) and specific surface area analyzer (BET).

Experimental results and discussion

The experimental results show that additive treatment can significantly reduce the silica content in light-burned magnesium oxide, thereby improving its purity. Physical property tests show that the morphology and specific surface area of the treated samples are not significantly affected.

Additive treatment is an effective method for removing silica from light-burned magnesium oxide, which can improve its purity and application performance. Future research will focus on optimizing the type and amount of additives to improve processing efficiency and reduce costs, and further expand the application range of light-burned magnesium oxide.