Light-burned powder hydration method: opening a new chapter in the green production of magnesium hydroxide flame retardant

Today, with the growing global demand for environmentally friendly and flame-retardant materials, magnesium hydroxide (Mg(OH)2) has become a hot spot in the market due to its excellent flame-retardant properties and environmentally friendly properties. The new process of producing flame-retardant magnesium hydroxide by light burning powder hydration method provides an innovative solution for the production of magnesium hydroxide with its characteristics of high efficiency, environmental protection and economy.

Analysis of the advantages of lightly burned powder hydration method

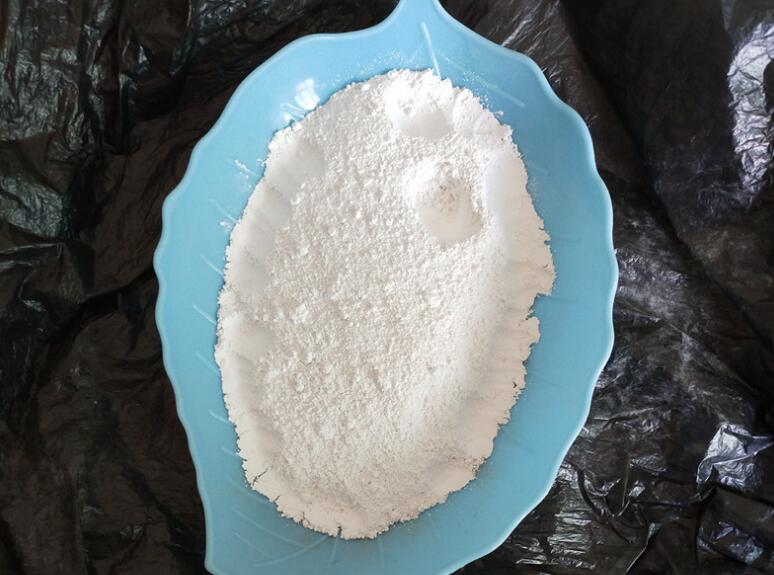

The light-burned powder hydration method is a new process that reacts light-burned magnesium oxide powder (light-burned powder) with water under specific conditions to generate high-purity magnesium hydroxide. This approach has the following significant advantages:

High-purity products: By precisely controlling reaction parameters, such as pH value and reaction temperature, magnesium hydroxide with a purity exceeding 98% can be produced to meet the needs of the high-end market.

Uniform particle size: The magnesium hydroxide particles produced by the new process have a uniform particle size distribution and regular morphology, which is beneficial to improving its dispersion and compatibility in polymer materials.

Green and environmentally friendly: The entire production process does not produce toxic and harmful gases, complies with current environmental protection regulations, and is a sustainable green production process.

Overview of key steps in the new process

The process of preparing magnesium hydroxide by light-burning powder hydration method includes the following key steps:

Pretreatment of lightly burned powder: improve the purity of the magnesium chloride solution through acidification, iron removal and other refining treatments, laying the foundation for subsequent reactions.

Hydration reaction: Under strictly controlled conditions, the refined magnesium chloride solution is reacted with sodium hydroxide to generate magnesium hydroxide.

Chemical impurity removal: By adding specific chemical impurity removal agents, impurities such as calcium, silicon, aluminum, and iron in magnesium hydroxide are removed to further improve product purity.

Surface modification: Surface organic modification of magnesium hydroxide to enhance its dispersion, compatibility and affinity in organic polymer materials.

Application prospects and market potential of new processes

Flame-retardant magnesium hydroxide produced by light-burning powder hydration method is expected to be widely used in plastics, rubber, coatings, wires and cables and other fields due to its high purity, uniform particle size and green environmental protection. As global demand for flame-retardant materials continues to grow, the market potential for this new process is huge.

The new process of producing flame-retardant magnesium hydroxide by light burning powder hydration method not only improves the quality and performance of the product, but also meets the requirements of environmental protection and safety. This innovative process is expected to play a greater role in the field of flame retardant materials in the future, providing strong support for achieving green and sustainable development, and also opening up new market opportunities for enterprises.