Preparation of magnesium hydroxide flame retardant using natural hydromagnesite: a new approach to improve the flame retardancy of EVA materials

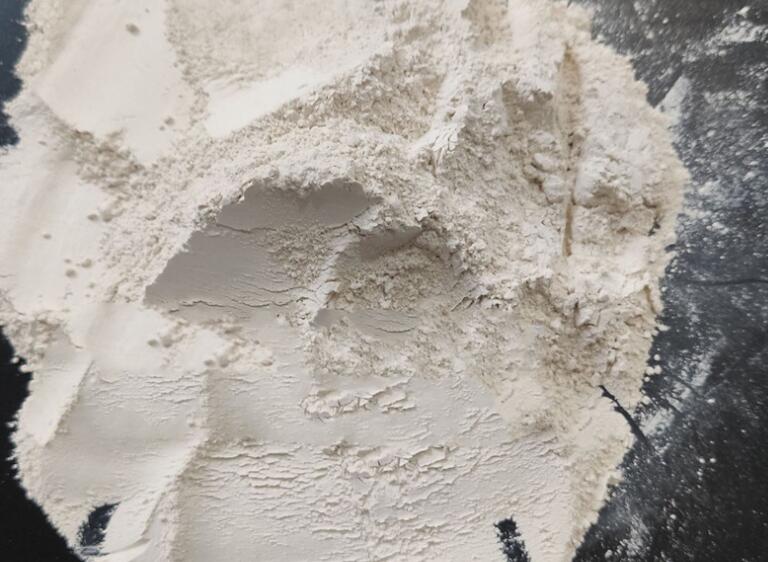

In the field of materials science, the development of environmentally friendly and efficient flame retardants is an important current research direction. Natural hydromagnesite, as a natural resource rich in alkaline magnesium carbonate, has become an ideal choice for the preparation of high-performance magnesium hydroxide (MH) flame retardants. Magnesium hydroxide has become an ideal halogen-free flame retardant due to its high decomposition temperature, good thermal stability, non-toxic and smoke-free, significant smoke suppression effect and no secondary pollution. This article will introduce in detail how to use natural hydromagnesite to prepare magnesium hydroxide flame retardant and explore its application in ethylene vinyl acetate (EVA) materials.

The application effect of magnesium hydroxide in EVA materials

Adding magnesium hydroxide as a flame retardant to EVA materials can significantly improve its flame retardant properties. Studies have shown that the limiting oxygen index (LOI) of EVA composite materials after adding magnesium hydroxide increases from 20% of pure EVA to about 38%. In addition, the addition of magnesium hydroxide also reduces the heat release rate (HRR) of the material, increases the coke residue rate, and increases the coke residue after combustion, thereby improving the thermal stability and flame retardant properties of the material.

Synergistic effect of modified magnesium hydroxide

In order to further improve the flame retardant effect of magnesium hydroxide, modified magnesium hydroxide flame retardant can be used. For example, by polymerizing lignin ester on the surface of magnesium hydroxide to form a surface modification layer, the compatibility between magnesium hydroxide and EVA resin can be improved, and the carbon-forming performance can be improved, thereby synergistically improving the resistance of magnesium hydroxide. The flame retardant effect of flame retardant. This method not only improves the flame retardant properties of the material, but also improves the mechanical properties of the material.

The magnesium hydroxide flame retardant prepared from natural hydromagnesite shows significant flame retardant effect in EVA materials. Through scientific and reasonable modification methods, the dispersion and compatibility of magnesium hydroxide can be further optimized, thereby more effectively improving the flame retardant and physical properties of EVA composite materials. The development and application of this environmentally friendly flame retardant not only conforms to the trend of modern green development, but also opens up new ways to improve material safety and environmental protection. As the market demand for environmentally friendly flame retardant materials continues to grow, the application prospects of magnesium hydroxide flame retardants based on natural hydromagnesite in EVA materials will become increasingly broad.