Excellent performance of magnesium hydroxide in adsorption and purification in environmental management

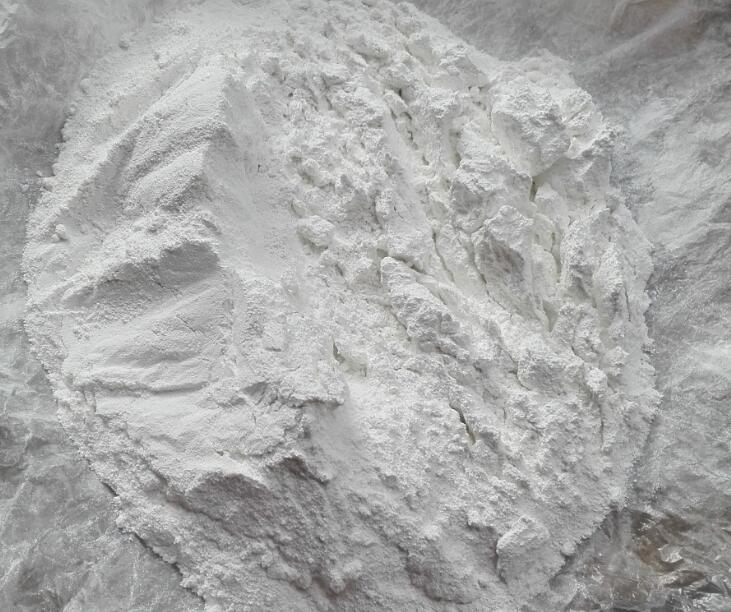

Research and development of efficient adsorbents

Magnesium hydroxide has good adsorption performance for a variety of pollutants due to its large specific surface area and abundant surface hydroxyl groups. Studies have shown that it has a strong adsorption capacity for heavy metal ions such as lead, cadmium, and mercury. It can fix heavy metal ions through ion exchange and chemical adsorption and remove heavy metal pollutants in water. It also has an adsorption effect on organic pollutants such as dyes and pesticides. The adsorption performance of organic pollutants can be improved through modification, such as loading active components and preparing composite materials. For example, the adsorbent composed of magnesium hydroxide and activated carbon has significantly improved adsorption capacity for organic dyes and good regeneration performance.

The key role of wastewater treatment

In industrial wastewater treatment, magnesium hydroxide is used to adjust pH and remove impurities and pollutants. It has moderate alkalinity and can neutralize acidic wastewater without introducing new pollutants. When treating phosphorus-containing wastewater, it reacts with phosphate ions to generate magnesium phosphate precipitate, which can effectively remove phosphorus. The researchers also explored methods for deep wastewater treatment, such as the combined micro-electrolysis-magnesium hydroxide precipitation process, which first converts difficult-to-degrade organic matter through micro-electrolysis, and then uses magnesium hydroxide precipitation to remove heavy metal ions and some organic matter, so as to achieve wastewater discharge that meets standards.

Application prospects of waste gas purification

Magnesium hydroxide has broad prospects in the field of waste gas purification. It can be used to remove pollutants such as sulfur dioxide and nitrogen oxides from industrial waste gas. For example, the slurry can be used for flue gas desulfurization, which has high desulfurization efficiency and the product magnesium sulfate can be recovered, thus achieving both economic and environmental benefits. In addition, researchers are exploring the use of magnesium hydroxide adsorbents to remove volatile organic compounds (VOCs). By modifying them to improve adsorption selectivity and capacity, they are expected to achieve efficient purification of VOCs in industrial waste gases.