High-performance environmentally friendly flame-retardant materials: innovative preparation and properties of magnesium hydroxide-agar composite aerogel

The preparation of magnesium hydroxide-agar composite aerogel and the study of its flame retardant properties is an interdisciplinary field involving multiple aspects such as materials science, chemical engineering and fire safety. The following is the basic framework for the preparation and performance evaluation of the composite material:

Preparation

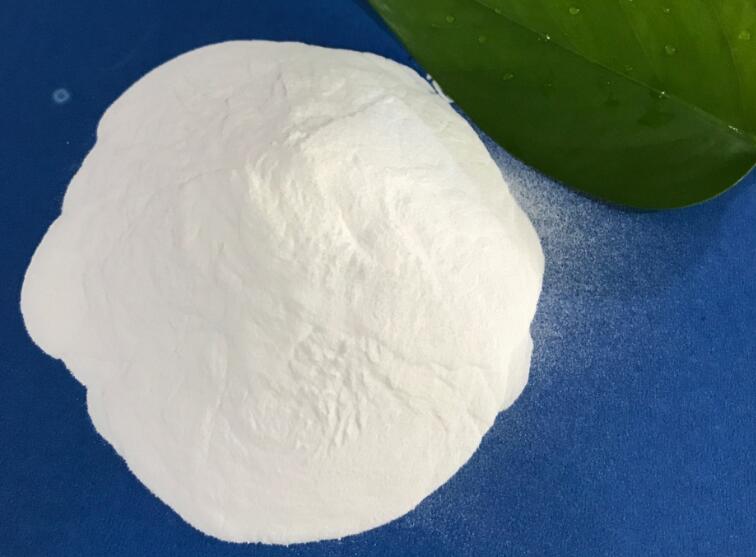

Raw material preparation: Select high-purity magnesium hydroxide (Mg(OH)_2) as the flame-retardant filler and natural polymer agar as the matrix material. Magnesium hydroxide requires surface treatment in advance to improve its compatibility with the agar matrix. Sol-gel process: Sol preparation: First dissolve agar powder in hot water, heat and stir until completely dissolved, forming a transparent agar sol. Magnesium hydroxide dispersion: The surface-modified magnesium hydroxide powder is evenly dispersed in the agar sol, and ultrasonic treatment or high-speed stirring is used to ensure that the magnesium hydroxide particles are evenly dispersed and avoid agglomeration. Gel molding: Pour the evenly mixed sol into a mold and solidify into a gel naturally at room temperature or low temperature. During this period, certain humidity and temperature conditions may need to be controlled to promote uniform gelation. Drying process: Using freeze-drying technology, the gel is frozen in a low-temperature and low-pressure environment, and then sublimated to remove the water to form a porous aerogel structure. This process is critical to maintaining the aerogel's microstructure. Flame retardant performance evaluation

Thermogravimetric analysis (TGA): Use a thermogravimetric analyzer to measure the mass change of the composite aerogel during the heating process, evaluate its thermal stability and weight loss behavior at high temperatures, and indirectly reflect the flame retardant effect. Limiting Oxygen Index (LOI) test: Determines the minimum oxygen concentration required for composite aerogels to maintain sustained combustion. The higher the LOI value, the better the flame retardant performance of the material. Cone calorimeter test: evaluate the heat release rate (HRR), total heat release, etc. of the material, which directly reflects the material's combustion performance and flame retardant efficiency under fire conditions. Vertical burning test (UL-94 test): According to the international safety standard UL-94, the flame retardant grade of the material is evaluated, including self-extinguishing properties, dripping conditions, etc. Performance characteristics and applications

Due to its unique structure and properties, magnesium hydroxide-agar composite aerogel exhibits good flame retardant properties. It also has the characteristics of light weight, high porosity and low smoke, which makes it have broad application prospects in the fields of construction, textiles, aerospace, etc. In particular, its environmental friendliness, halogen-free, low toxicity and low smoke make it an ideal choice for the new generation of environmentally friendly flame retardant materials. By optimizing the preparation process and component ratio, its mechanical properties and flame retardant efficiency can be further improved, and its application range can be broadened.