Effect of melamine on flame retardancy of silicone rubber/magnesium hydroxide/hydrotalcite composites

Melamine has a significant impact on the flame retardant properties of silicone rubber/magnesium hydroxide/hydrotalcite composite materials, which is mainly reflected in the following aspects:

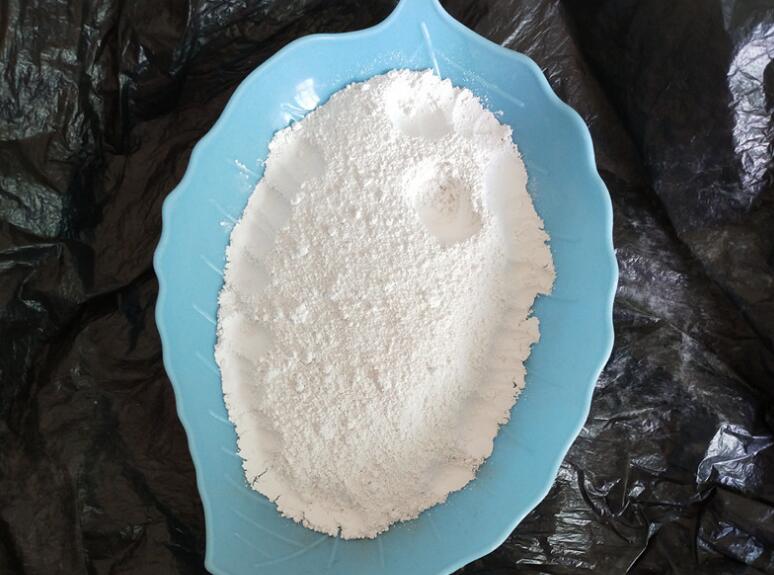

Improving flame retardant efficiency: Melamine, as a nitrogen-containing compound, can decompose at high temperatures to produce non combustible gases such as nitrogen and ammonia. These gases can dilute combustible gases, form an isolation layer, and thus suppress material thermal decomposition and flame spread. In addition, it can also promote the formation of a carbonization layer, improve the carbonization rate of the material, and the carbon layer serves as an insulation barrier, effectively preventing heat transfer and oxygen entry, enhancing the flame retardant effect. Optimization of microstructure: The addition of melamine can affect the microstructure of composite materials. Through the synergistic effect with magnesium hydroxide (Mg (OH) 2) and hydrotalcite (LDHs), it can promote more uniform dispersion, reduce the aggregation phenomenon of flame retardants, improve the density of materials and the effective utilization rate of flame retardants. Enhanced interface interaction: Melamine may form strong interactions with silicone rubber matrix, magnesium hydroxide, and hydrotalcite, such as hydrogen bonding, which helps to enhance the bonding strength between each component, improve the overall mechanical properties of the composite material, and also help to form a more stable protective layer during combustion, improving flame retardancy and durability. Impact on thermal decomposition behavior: The addition of melamine may alter the thermal decomposition path and heat release rate of composite materials. Through complex thermal decomposition reactions, more inert residues may be generated, reducing the release of harmful smoke and improving fire safety. Improving mechanical and processing properties: Reasonable addition of melamine can not only enhance flame retardancy, but also improve the mechanical properties of materials to a certain extent, such as tensile strength, tear strength, etc. At the same time, the addition of melamine may also affect the fluidity and processing properties of materials, making it easier for the forming and processing of composite materials. In summary, melamine, as a flame retardant additive, effectively improves the flame retardant performance of silicone rubber/magnesium hydroxide/hydrotalcite composite materials through multiple mechanisms, and also has a positive regulatory effect on their overall performance. However, the optimal dosage and specific effects still need to be explored in detail through experiments to achieve the best balance between flame retardancy and other properties.