Performance analysis of fluidized bed reactor of magnesium hydroxide thermochemical heat storage system

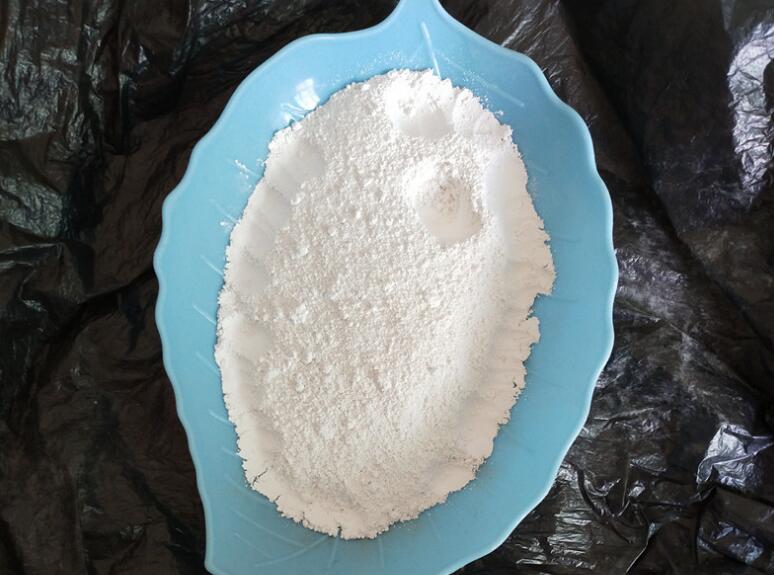

The fluidized bed reactor in the magnesium hydroxide (Mg(OH)_2) thermochemical heat storage system is a core device that efficiently utilizes chemical reactions for heat storage and release. This type of system stores and releases energy through the dehydration-hydration reaction of magnesium hydroxide, and has the characteristics of high energy storage density and good cycle stability. In a fluidized bed reactor, magnesium hydroxide particles come into contact with gas (usually air or water vapor) under certain temperature and pressure conditions to achieve effective exchange of heat energy. The following are several key analysis points on the performance of the fluidized bed reactor in the magnesium hydroxide thermochemical heat storage system:

1. Fluidization characteristics analysis

Critical fluidization velocity: The minimum gas velocity that determines the normal operation of the fluidized bed. Below this velocity, the bed does not flow, and above this velocity, it enters the fluidized state. Maximum fluidization velocity: Above this velocity, the bed may enter the turbulent or rapid fluidization stage, affecting the reaction efficiency and equipment stability. Pressure drop characteristics: Measure the relationship between the bed pressure drop and the gas velocity to evaluate the fluidization quality and prevent excessive pressure loss. Solid particle distribution: Analyze the uniformity of solid particles in the bed to ensure sufficient reaction contact and avoid local overheating or cold spots. 2. Heat transfer efficiency

Heat transfer coefficient: evaluates the efficiency of heat transfer in the fluidized bed, which is affected by the gas-solid contact area, fluid properties and bed structure. Temperature distribution: through experiments and simulations, understand the temperature distribution inside and on the surface of the bed to ensure uniform reaction and effective use of heat energy. Thermal mass and energy storage density: evaluate the heat storage capacity per unit volume or mass, which affects the overall energy storage efficiency and economy of the system. 3. Chemical reaction kinetics and thermodynamics

Reaction rate: Analyze the rate of magnesium hydroxide dehydration and hydration reaction under different operating conditions (such as temperature, gas velocity, catalyst) to optimize the reaction conditions. Thermal effect: Calculate the endothermic and exothermic effects during the reaction to ensure the thermal balance of the system and avoid thermal runaway or inefficiency. Cyclic stability: Investigate the performance changes of the reactor after multiple charging and discharging cycles to evaluate material aging, agglomeration and activity retention. 4. Optimization of structure and operating parameters

Catalyst selection and layout: Optimize the type, loading and distribution of catalysts to improve reaction efficiency and stability. Gas distribution device: Design a reasonable gas distribution plate to ensure uniform distribution of gas flow and avoid local overheating and catalyst wear. Control system design: Including temperature, pressure, and flow control to ensure precise control of reaction conditions and improve system safety and reliability. 5. Economic and environmental assessment

Cost-benefit analysis: Consider material costs, equipment investment, and operation and maintenance costs to evaluate the economic feasibility of the entire system. Environmental impact: Analyze the energy consumption, emissions, and waste material handling methods during system operation to ensure environmental friendliness. In summary, the performance analysis of the fluidized bed reactor in the magnesium hydroxide thermochemical heat storage system involves many considerations, from basic fluid mechanics to complex chemical reaction kinetics, to system economics and environmental impacts. The optimization of each link is the key to improving the overall performance of the system. Through in-depth research and technological innovation, the efficiency, reliability, and economy of this type of heat storage system can be further improved, promoting its widespread application in solar thermal power generation, industrial waste heat recovery and other fields.