High-performance liquid precipitation method: an innovative technology for preparing high-purity ultrafine flame-retardant magnesium hydroxide

Liquid precipitation method is a commonly used chemical synthesis method for preparing high-purity, ultra-fine particle materials, including flame-retardant magnesium hydroxide (Mg(OH)2). The following is an overview of the specific process flow for preparing high-purity ultrafine flame-retardant magnesium hydroxide using liquid phase precipitation method:

Raw material selection and ratio

Main raw materials: Magnesium sulfate (MgSO_4_) is generally used as the magnesium source, and sodium hydroxide (NaOH) is used as the precipitant. Other possible sources of magnesium include magnesium chloride (MgCl_2_). Additives: In order to improve particle morphology, control particle size and improve dispersion, an appropriate amount of surfactant will be added, such as sodium stearate (NaSt), polyethylene glycol (PEG2000) or other dispersants (such as dodecane sodium sulfate). Optimization of process conditions

Precipitation method: Bidirectional precipitation can more effectively control the precipitation process and improve the uniformity and purity of the product. Reactant ratio: The optimized n(NaOH) : n(MgSO_4_) ratio is 2.5 : 1.0 to ensure sufficient precipitation and reduce the generation of by-products. Reaction conditions: Control the reaction temperature to 60°C, the stirring rate to 400 r/min, and the reaction time to 50 minutes to promote uniform precipitation and crystal growth. Use of surfactants: The ratio of surfactants (NaSt and PEG2000) is 4:1, and the total amount is 4 g/mol magnesium source, which helps to form ultra-fine particles and prevent agglomeration. Washing and post-processing: Wash with pure water several times to remove impurities and ensure high purity of the product. Performance testing and evaluation

Product testing: After completion of synthesis, the morphology (such as SEM, TEM), crystal phase structure (XRD), particle size and distribution (laser particle size analyzer), purity (chemical analysis), dispersion effect and wetting of the obtained magnesium hydroxide are carried out. performance testing. Flame retardant performance evaluation: In practical applications, it is also necessary to evaluate its flame retardant efficiency in resins or other polymers, including limiting oxygen index (LOI), heat release rate (THR), smoke density and other indicators. Laboratory and industrial considerations

After successful preparation on a laboratory scale, the continuity and cost-effectiveness of large-scale production must also be considered, including the continuous supply of raw materials, reactor design, thermal energy management, and continuous separation and drying of products, to ensure the consistency and economy of industrial production.

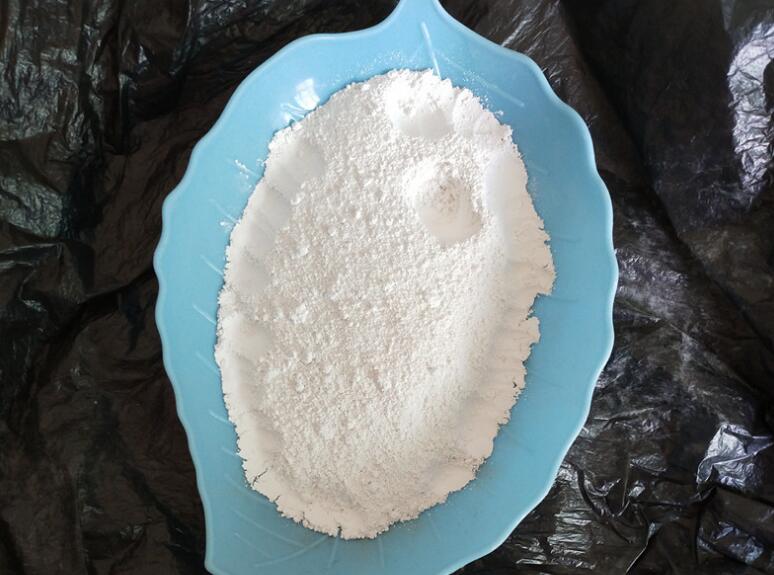

In summary, through a carefully designed liquid phase precipitation process, high-purity, ultrafine magnesium hydroxide powder with excellent flame retardant properties can be effectively prepared to meet the needs of the high-end flame retardant material market.