Talc, a ubiquitous silicate mineral, is known for its soft touch and unique slippery feel. Its natural forms are diverse, and can be massive, flaky, fibrous or radial. The main color is pure white or off-white, but the involvement of impurities makes it rich in color.

Application areas and feature highlights:

The darling of the ceramic manufacturing industry: talc plays an important role in the manufacture of high-frequency ceramics, radio ceramics, industrial ceramics, architectural ceramics, daily life ceramics and ceramic glazes. It can not only maintain color stability under high temperature conditions, but also appear whiter after calcination, and has uniform density distribution, giving the products excellent gloss and smooth surface. Its non-discoloration characteristics under high temperature and whitening effect after calcination, coupled with the advantages of uniform density, bright gloss and smooth surface, make the final product more beautiful and durable.

Selection of reinforced modified filling materials: In slippery industries such as rubber, plastic products, and paints, talc powder shows excellent performance as a reinforced modified filler. It can significantly improve the morphological stability of the product, enhance its tensile strength, shear strength, bending strength and ability to withstand pressure, while effectively reducing the deformation rate, elongation and thermal expansion coefficient of the material. Talcum powder is famous for its high whiteness, uniform particle size, and good dispersion. These characteristics comprehensively improve the overall quality and performance of the product.

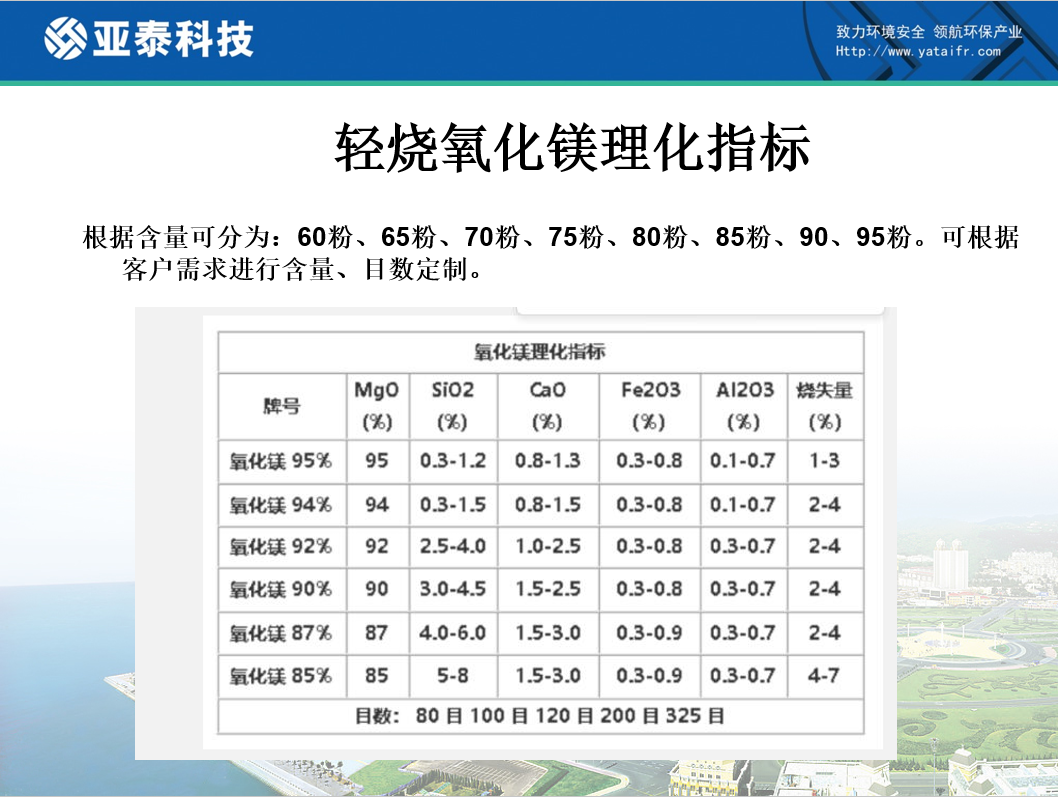

Product Specifications:

Magnesium oxide (MgO) content: guaranteed to be at least 30% to ensure the chemical stability of the material. Silicon dioxide (SiO2) content range: flexibly controlled between 15% and 60% to meet different application needs. Calcium oxide (CaO) and iron oxide (Fe2O3) content: strictly controlled within 1% to reduce the impact of impurities and improve purity. Particle size specification: Provides a wide range of choices from 200 to 5000 mesh, suitable for various processing needs from fine to extensive, ensuring suitable dispersion and filling effect of materials in different applications. The wide application and optimization of properties of talc reflect its unique value as a multifunctional mineral material. It not only promotes the dual improvement of artistic beauty and practical performance in the ceramic industry, but also provides efficient material enhancement and improvement for plastics, rubber and other industries. solution.