Type: Carrier-free masterbatch

Input Size:

Processed Materials:

Applications:

Carrier-free masterbatch

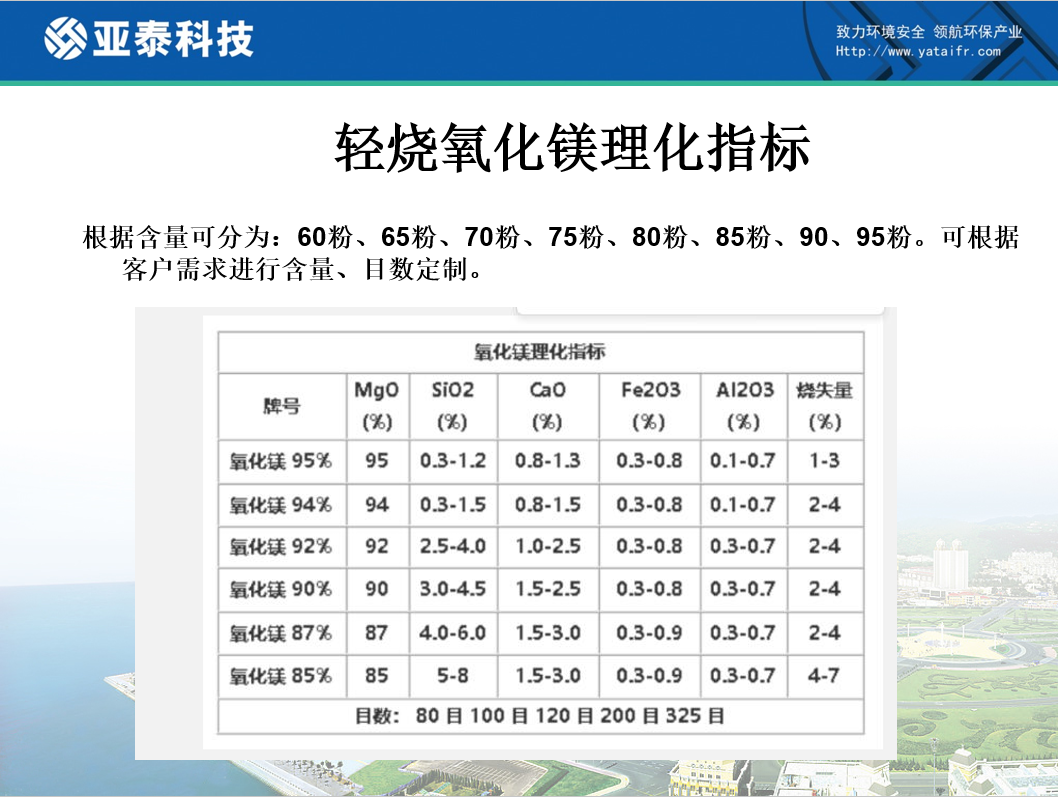

Product Overview: The carrier-free masterbatch launched by Yatai Technology marks a new era of highly filled masterbatch that pays equal attention to environmental protection and performance. Through fine granulation processing, functional enhancement and dust-free design, this product effectively promotes the efficient use of inorganic powder materials, not only significantly enhances product quality, but also significantly reduces production costs, while completely solving production problems. The common dust pollution problem in the environment perfectly complies with the double high standards of environmental protection and production efficiency in modern industry.

Features:

Personalized customized solutions: Provide a variety of talc, brucite, calcium carbonate and other powder options to meet the specific needs of customers. Pure formula design: eliminate the addition of additional resin to ensure the purity of the masterbatch and improve the purity of the product. Advanced surface activation technology: The innovative surface activation process is adopted to effectively prevent the backflow of materials during the granulation process and greatly improve production efficiency. Green production practices: reduce dust, simplify the adding process, strengthen dispersion and filling rate, and fully implement the concept of environmental protection. Significant economic benefits: optimize logistics costs, enhance product value, and create greater profit margins for enterprises. Flexible addition ratio: The recommended addition range is 5% to 45%, which can be flexibly adjusted according to different application requirements to achieve the best performance. High-performance powder core: The masterbatch contains more than 90% powder, and uses general-purpose additives and resins to ensure superior product performance. Efficient production process: optimize the granulation process, eliminate the phenomenon of material return, and further improve the efficiency of the production line. Excellent product performance: Improve the surface finish of products, strengthen dimensional stability, reduce internal stress and cracks, and comprehensively improve product quality. Wide application scenarios: In the engineering plastics manufacturing industry, as an ideal substitute for talc powder, it is widely integrated into the production of plastic products, and is especially favored by companies that pursue environmental protection and efficient production models. Yatai Technology, as a high-tech leader in the field of new materials in China, continues to be committed to the research and development of innovative, environmentally friendly and high-performance materials. Our carrier-free masterbatch is the crystallization of profound R&D strength and technological innovation, aiming to provide global customers with a safe, efficient, and environmentally friendly industrial material solution, and jointly promote industrial upgrading and green development.