Application of in-situ magnesium hydroxide generation technology in treatment of produced water from ASP flooding

Alkaline-Surfactant-Polymer (ASP) technology is introduced as an effective means to improve crude oil recovery, and the problem of produced water treatment generated during its application has always been the focus of the industry. In Situ Generated Magnesium Hydroxide (IFM) technology has shown great potential in this field with its environmental friendliness, high efficiency and economy.

Features of In Situ Magnesium Hydroxide Technology

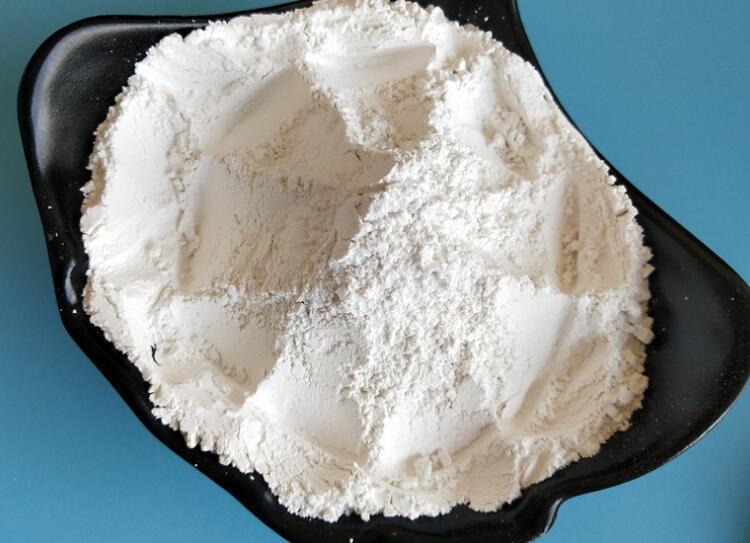

· Environmental friendliness: using natural magnesium sources, converting them into magnesium hydroxide precipitation through conditional control, reducing chemical additions.

· High efficiency: magnesium hydroxide is used as a flocculant to effectively adsorb and remove organic matter and metal ions in water.

· Economic efficiency: reducing the cost of chemical agents and utilizing existing magnesium sources.

· Multifunctionality: removing suspended solids and emulsified oil, adjusting pH value, and assisting subsequent treatment.

Treatment effect study

Research background

Ternary composite flooding produced water contains polymers, alkalis and surfactants, which increase the difficulty of oil-water separation. Traditional treatment methods have limitations in removing these pollutants.

Technical principle

By adding magnesium salt and controlling the pH value, magnesium hydroxide precipitation is generated, and its adsorption properties are used to remove pollutants.

Experimental design

· Raw materials and reagents: magnesium sulfate or magnesium chloride as magnesium source, ammonia water or lime water to adjust pH value.

· Experimental conditions: pH value, magnesium salt dosage, reaction time, stirring speed, etc.

· Performance evaluation: Determine the content of pollutants before and after treatment and evaluate the effect.

Results and discussion

· Removal efficiency: IFM technology effectively removes emulsified oil, suspended solids, etc.

· Economic analysis: The cost is lower than traditional methods.

· Environmental impact: Magnesium hydroxide precipitation is environmentally friendly and easy to separate.

Practical application

Optimize laboratory-scale reaction conditions and determine the optimal parameters. Consider combining with other technologies to improve treatment efficiency.

The in-situ generation of magnesium hydroxide technology provides an effective solution for the treatment of produced water from ternary composite flooding, with significant economic and environmental benefits. Future research will explore technical optimization in large-scale practical applications.

The application of IFM technology in water treatment is not limited to the petroleum industry. Its environmentally friendly and efficient characteristics are also suitable for municipal and industrial wastewater treatment, and it has broad market application prospects.