Study on the application of ammonia precipitation method in the preparation of magnesium hydroxide

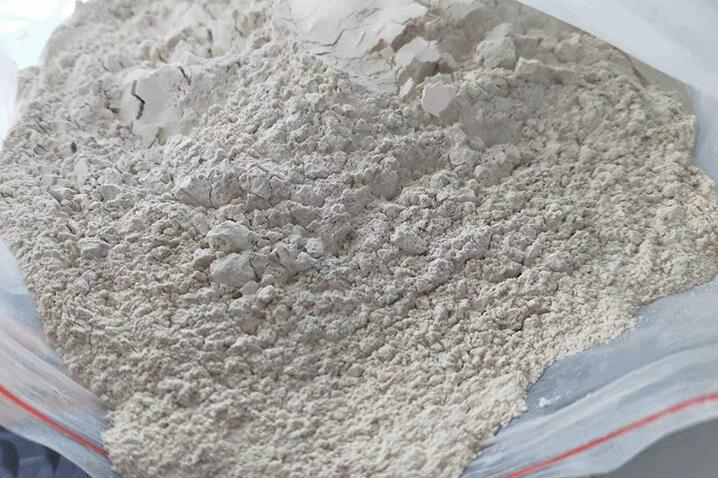

Magnesium hydroxide (Mg(OH)₂), as an important inorganic compound, is widely used in flame retardants, adsorbents, catalyst carriers and other fields. As a mature synthesis method, the ammonia precipitation method can effectively control the particle size, morphology and purity of magnesium hydroxide by finely regulating the reaction conditions.

Basic principles of ammonia precipitation method

The ammonia precipitation method uses ammonia as a precipitant to react with a magnesium-containing salt solution to form magnesium hydroxide precipitate. The basic reaction equation is: Mg2++2NH3⋅H2O→Mg(OH)2↓+2NH4+Mg2++2NH3⋅H2O→Mg(OH)2↓+2NH4+

Factors affecting the properties of magnesium hydroxide

· pH value of ammonia water: pH value affects the particle size and settling time of magnesium hydroxide.

· Ammonia flow rate: The speed of the rate affects the particle size and morphology.

· Ammonia-magnesium ratio: Different ratios have significant differences in product properties.

· Reaction temperature: Temperature has an important impact on reaction speed and crystallinity.

· Additives: such as ammonium chloride, etc., can regulate the growth process of magnesium hydroxide.

Experimental research content

· Raw material preparation: Choose magnesium sulfate or magnesium chloride solution as the magnesium source.

· Optimize reaction conditions: adjust pH value, ammonia flow rate, etc., and observe changes in product characteristics.

· Product characterization: Use SEM, TEM, XRD, TGA and other technologies to conduct detailed analysis of the product.

· Performance testing: Evaluate the flame retardancy, hygroscopicity, thermal stability, etc. of magnesium hydroxide.

· Preparation of magnetic composite materials: Add magnetic particles to prepare magnetic magnesium hydroxide composite materials.

Application direction

· Flame retardant: Magnesium hydroxide acts as an efficient halogen-free flame retardant.

· Adsorbents: take advantage of their high specific surface area properties.

· Catalyst support: Provides active sites.

· Magnetic composite materials: applications in wastewater treatment and other fields.

The preparation of magnesium hydroxide by the ammonia precipitation method is a multi-variable chemical process. By systematically optimizing the reaction conditions, magnesium hydroxide with specific characteristics can be synthesized to meet the needs of different industrial applications. This method provides an efficient and controllable way for the industrial production of magnesium hydroxide.