Application of magnesium hydroxide as a new alkali source in the bleaching process of waste paper deinking pulp and its effect on oxalate formation

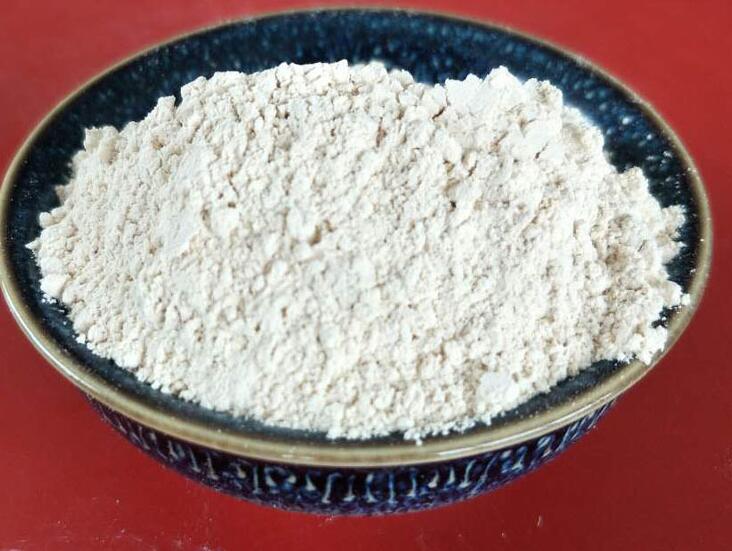

In the process of green transformation of paper industry, environmentally friendly bleaching technology of waste paper deinking pulp has become a hot topic of research. Traditionally, sodium hydroxide (NaOH) is often used as an alkali source in the bleaching process, but this method has problems such as environmental pollution, yellowing of paper and equipment scaling. In order to solve these problems, hydrogen peroxide bleaching technology with magnesium hydroxide (Mg(OH)₂) as an alkali source has received widespread attention.

This paper will explore the application of magnesium hydroxide in the hydrogen peroxide bleaching process of waste paper deinking pulp and analyze its effect on the formation law of oxalate (C₂O₄²⁻). Oxalate, as a common by-product in the bleaching process, may cause equipment scaling, affecting bleaching efficiency and paper quality.

The study found that in the process of magnesium hydroxide-based alkali source hydrogen peroxide bleaching, the generation of oxalate is closely related to the bleaching conditions. As the proportion of magnesium hydroxide replacing sodium hydroxide increases, the consumption of hydrogen peroxide decreases, and the chemical oxygen demand (COD) also decreases. Especially under the condition of 50% magnesium hydroxide substitution rate, the whiteness of bleached pulp and paper strength reached the optimal value.

Mechanistic analysis shows that the use of magnesium hydroxide may reduce the formation of oxalate by changing the mechanism of the bleaching reaction. Lower COD means less pollution load, thereby improving the environmental impact of bleaching wastewater.

Using magnesium hydroxide as an alkali source can not only effectively control the formation of oxalate, but also improve bleaching efficiency and paper quality. The appropriate magnesium hydroxide replacement ratio can significantly improve the economy and environmental friendliness of the bleaching process. These research results are of great significance for optimizing the bleaching process and reducing the impact on the environment.

If you need to obtain more specific data or experimental details, you can refer to relevant papers and literature for more in-depth information. At the same time, with the continuous progress in the field of ecological and environmental functional materials, magnesium hydroxide has broad application prospects in the papermaking industry as an environmentally friendly material.