Optimization research and application exploration of magnesium hydroxide carbonization process

The carbonization process of magnesium hydroxide (Mg(OH)2), that is, the process of converting magnesium hydroxide into magnesium carbonate (MgCO3), is an important chemical reaction that is widely used in chemical industry, environmental protection, materials science and other fields. This process mainly involves the reaction of magnesium hydroxide and carbon dioxide (CO2) under certain conditions. The following are several key points in the study of the carbonization process of magnesium hydroxide:

Reaction principle: The basic chemical equation for the reaction of magnesium hydroxide and carbon dioxide is:

Mg(OH)2+CO2MgCO3+H2OMg(OH)2+CO2MgCO3+H2O This means that under the right conditions, magnesium hydroxide can absorb carbon dioxide from the environment and convert it into magnesium carbonate.

Influencing factors:

Liquid-to-solid ratio: Studies have shown that the liquid-to-solid ratio (i.e., the mass ratio of water to magnesium hydroxide in the magnesium hydroxide slurry) has a significant impact on the carbonization effect. It is generally believed that a reasonable liquid-to-solid ratio can improve the absorption efficiency of carbon dioxide and optimize reaction conditions. Temperature: The temperature of the carbonization reaction is also an important factor. Studies have pointed out that carbonization at normal temperature or slightly higher than normal temperature can effectively control the reaction rate and product quality. Carbon dioxide gas velocity: Appropriately increasing the ventilation velocity of carbon dioxide can improve the contact efficiency between the gas and the solid surface, thereby accelerating the carbonization process. Stirring speed: Efficient stirring can enhance the mixing uniformity of materials, increase the reaction contact area, and have a positive impact on carbonization efficiency. Particle size of magnesium hydroxide: The smaller the particle size, the larger the surface area, which is beneficial to improving the reaction rate and product uniformity. Optimization of process conditions: In specific studies, it was found that the optimal conditions are a liquid-to-solid ratio of 40, a carbon dioxide gas velocity of 400 mL/min, and a stirring speed of 300 r/min. The carbonization effect under these conditions is the best, indicating that hydrogen oxidation The conversion rate of magnesium and the purity of the product are relatively high.

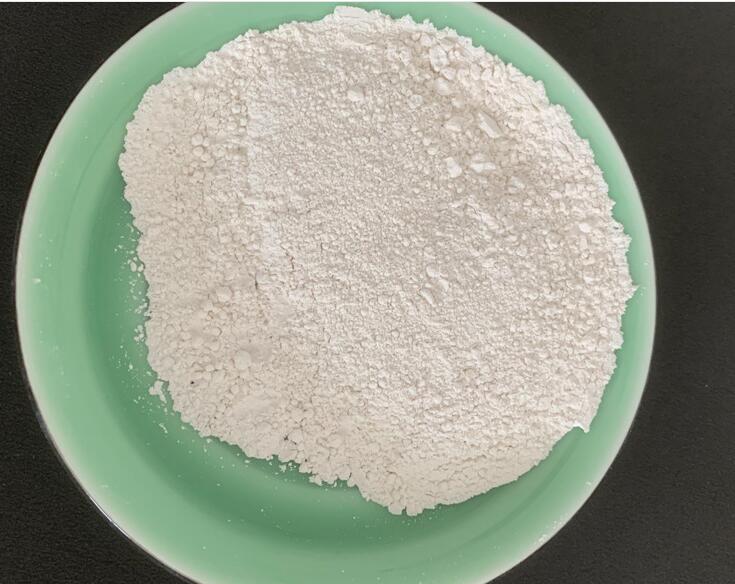

Product characteristics: By optimizing the carbonization process, magnesium carbonate products with high purity, good dispersion and specific morphology can be obtained. These characteristics are crucial to the final application performance of the product.

Application areas: Magnesium carbonate products produced by carbonization are widely used in plastics, rubber fillers, medicines, food additives, environmentally friendly desulfurizers and other fields. Its properties and purity directly affect the effects of these applications.

In summary, the carbonization process of magnesium hydroxide is a complex but controllable chemical reaction. By adjusting the reaction conditions, the properties of the product can be effectively controlled to meet the needs of different application fields. Continuous research and optimization are of great significance to improving product quality, reducing costs and developing new application fields.