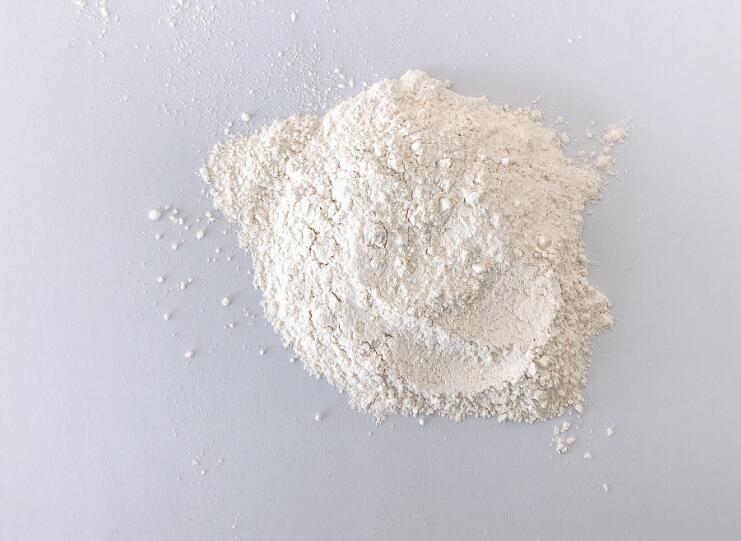

Magnesium hydroxide particle size has a significant impact on the structure and properties of corundum-spinel materials

Magnesium hydroxide particle size has a significant impact on the structure and properties of corundum-spinel materials, which is mainly reflected in the following aspects:

Dispersibility and compatibility: The smaller the particle size of magnesium hydroxide, the easier it is to disperse evenly in the material, and the larger the contact area with the corundum-spinel matrix, which is conducive to forming a denser structure and improving the overall compatibility and bonding strength of the material. On the contrary, a larger particle size may lead to agglomeration, affecting the uniformity and performance of the material.

Flame retardant properties: In flame retardant applications, fine magnesium hydroxide particles can more effectively absorb heat during combustion and release water vapor, playing a role in cooling and diluting oxygen, thereby improving the flame retardant efficiency of the material. The particle size directly affects the dispersion of the flame retardant in the material, which in turn affects the stability of the flame retardant effect.

Mechanical properties: Appropriate magnesium hydroxide particle size can optimize the mechanical properties of the material, such as bending strength, impact resistance, etc. Too large or too small a particle size may lead to a decrease in mechanical properties. For example, too large a particle size may reduce the toughness of the material, while too small a particle size may increase the brittleness of the material.

Microstructure: Particle size directly affects the microstructure of the material. Small and evenly distributed magnesium hydroxide particles can promote the refinement of grains in the material, which is beneficial to improve the density of the material and reduce defects, thereby enhancing the physical and chemical properties of the material.

Thermal conductivity and thermal stability: Particle size distribution has an important influence on the thermal conductivity of the material. Finer particles help form a more compact packing structure, which may improve the thermal conductivity of the material, which is especially important for applications that require good heat dissipation. At the same time, particle size also affects the thermal stability of the material. Materials with uniform particle size have better structural stability at high temperatures.

Corrosion resistance and wear resistance: In some applications, such as refractory materials, the particle size of magnesium hydroxide affects the smoothness and density of the material surface, which in turn affects its corrosion resistance and wear resistance. Finer particle size helps to form a smoother surface, reduce the intrusion of corrosive media, and improve the durability of the material.

Therefore, when designing and manufacturing corundum-spinel materials, it is crucial to select the appropriate magnesium hydroxide particle size to achieve the purpose of optimizing material properties. In practical applications, it is usually necessary to determine the optimal particle size range through experiments to meet specific performance requirements.